Breakage & Prevention

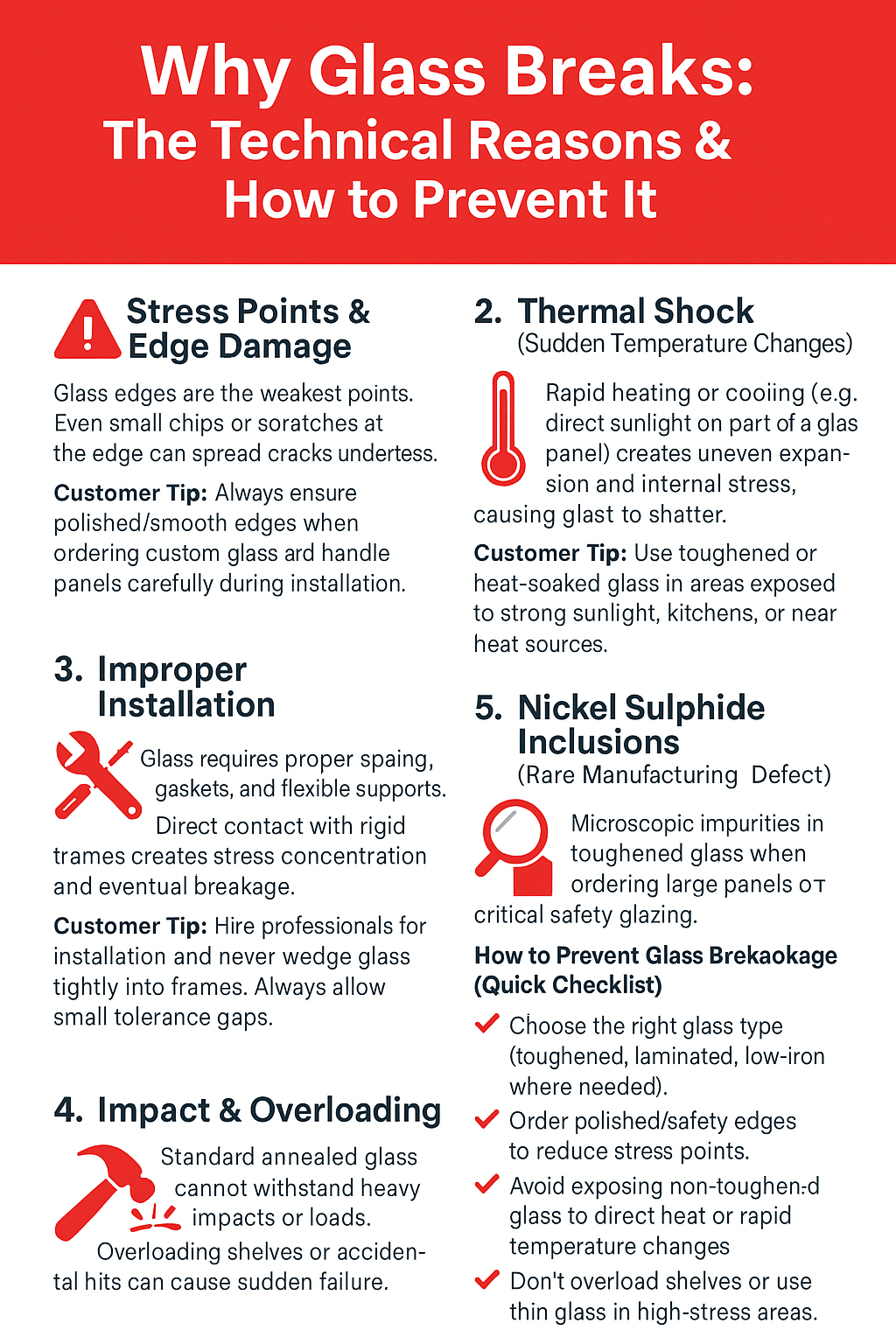

Why Glass Breaks: The Technical Reasons & How to Prevent It

Most glass failure isn’t random. It comes from edges, heat, installation, loads—or rare inclusions. Use this quick, customer-friendly guide to prevent breakage and choose the right glass every time.

Customer-Safe Choices

BS/EN Compliant

Quick Checklist

BS/EN Compliant

Quick Checklist

The Main Technical Reasons Glass Breaks

1) Stress Points & Edge Damage

Edges are the weakest area. Micro-chips or scratches act as crack starters under load.

- Prevent it: Order polished/safety edges; protect edges during handling and fitting.

2) Thermal Shock

Rapid temperature change creates uneven expansion and internal tension until failure.

- Prevent it: Use toughened or heat-soaked glass near cookers, radiators, or strong sun.

3) Improper Installation

Rigid frames, missing gaskets, or zero clearance create stress concentrations.

- Prevent it: Use setting blocks & soft gaskets; allow tolerance—never wedge glass tight.

4) Impact & Overloading

Annealed glass isn’t designed for heavy knocks or loads.

- Prevent it: Choose toughened/laminated for shelves, doors, balustrades; follow thickness & load limits.

5) Nickel Sulphide Inclusions (Rare)

Microscopic impurities in toughened glass can expand over time and trigger spontaneous breakage.

- Prevent it: Specify heat-soaked toughened glass for large or critical safety panels.

Quick Reference: Choose the Right Glass

| Situation | Recommended Choice | Why |

|---|---|---|

| Near heat / strong sunlight | Toughened or Heat-Soaked | Resists thermal shock |

| Shelves, doors, balustrades | Toughened / Laminated | Impact resistance & safer break mode |

| Overhead / skylights | Laminated | Stays in place if broken |

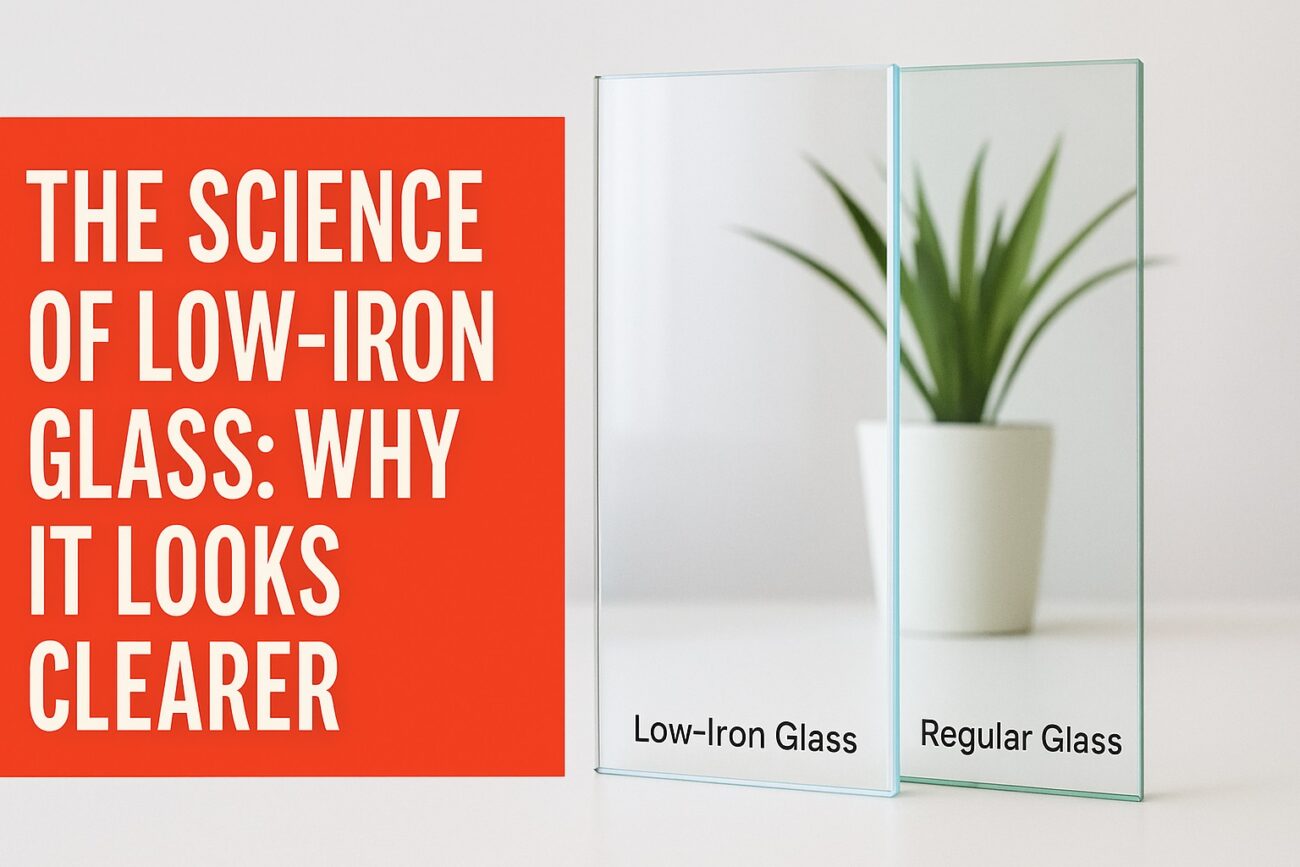

| Premium clarity surfaces | Low-iron (as needed) | Reduces green tint; check thickness & load |

How to Prevent Glass Breakage (Checklist)

- Pick the right glass type (toughened, laminated, heat-soaked) for the location.

- Order polished/safety edges to remove stress starters.

- Allow tolerance & soft gaskets—avoid hard frame contact.

- Avoid rapid heat changes on non-toughened glass.

- Respect thickness & load limits on shelves/doors.

- Buy BS/EN-compliant products from trusted suppliers.

All products supplied by Glass Help Ltd are made to order and adhere to the relevant BS/EN standards where applicable.

Leave a comment